Under the Health and Safety at Work etc Act 1974, employers have a duty to understand, assess, and control the risks of legionella bacteria. Keep reading to learn more about the actions this involves.

1. Understand what Legionnaire’s disease is

Legionnaire’s disease is a form of pneumonia caused by Legionella bacteria, which can be found in both natural water sources as well as purpose-built water systems.

Legionnaire’s disease is a form of pneumonia caused by Legionella bacteria, which can be found in both natural water sources as well as purpose-built water systems.

The disease is potentially fatal, and anyone can catch it. However, some groups are at a higher risk, including those:

- over 45 years old

- with an impaired immune system

- who smoke or drink heavily

- with diabetes,

- with lung, heart, kidney, or chronic respiratory disease

2. Know where it comes from and how people catch it

Legionella bacteria, while widespread in natural water systems, is unlikely to make you ill as it requires specific conditions to thrive. Legionnaires’ disease is most often caught from exposure to legionella growing in purpose-built systems, such as spa pools, hot and cold water systems, and cooling towers, as these keep water at a temperature high enough to encourage growth.

Water conditions that increase the risk of legionella growth include:

- water temperature between 20-45 °C

- storing or re-circulating water

- the possibility for water droplets to be created and dispersed

- if there are deposits in the water that can help support bacterial growth

Legionnaires’ disease is contracted when someone inhales small droplets of water in the air containing the bacteria.

3. Identify if there are Legionella risks in your workplace

If your water system meets any of the above conditions, or if your workplace has man-made water systems, you should carry out a risk assessment, especially if it is likely that any of your employees, residents, visitors etc are more susceptible and could be exposed to any contaminated water droplets.

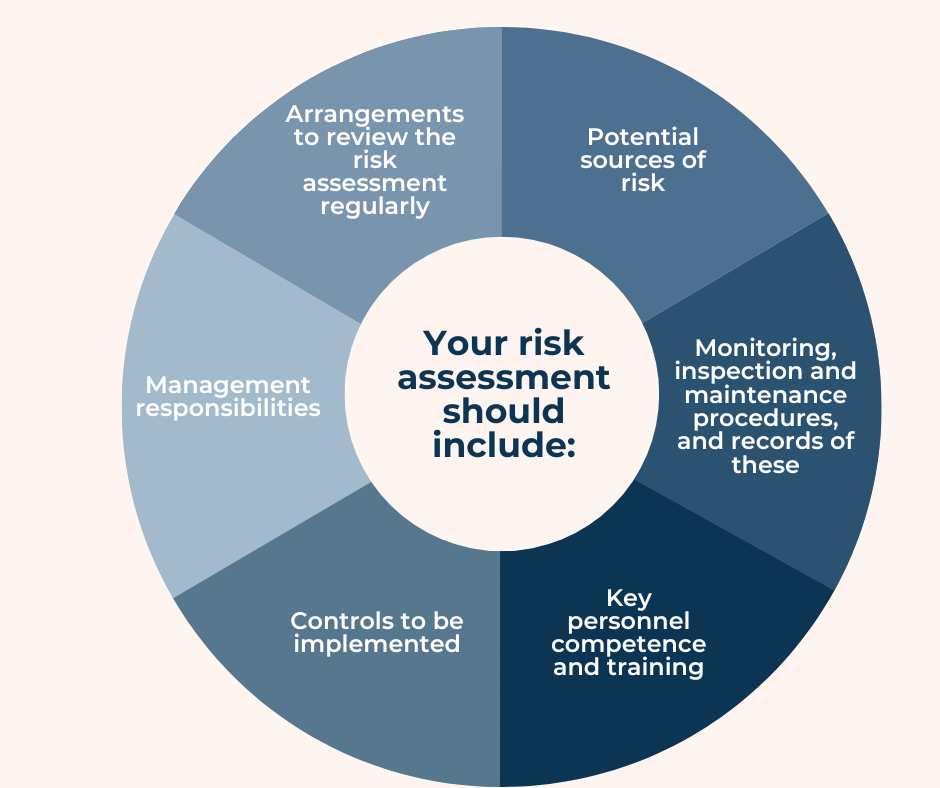

4. Carry out a risk assessment

Your risk assessment should be comprehensive and include:

Your risk assessment should be comprehensive and include:

- potential sources of risk

- monitoring, inspection and maintenance procedures, and records of these

- key personnel competence and training

- controls to be implemented

- management responsibilities

- arrangements to review the risk assessment regularly

5. Appoint a responsible person

Once you have identified the controls needed to mitigate the risk of legionella, you need to appoint a responsible person to manage these controls and ensure that tasks are carried out in a safe, technically competent manner.

You can appoint anyone, provided they have sufficient authority, competence, skills and knowledge about the installation to implement the controls and ensure that all operational procedures are carried out.

6. Implement controls

Ideally, you would be able to prevent the risk entirely by looking into different types of water system e.g. replacing a wet cooling tower with a dry air-cooled system. However, this will not always be possible, in which case you will need to design, maintain and operate your water services under conditions that prevent or adequately control legionella growth.

Ideally, you would be able to prevent the risk entirely by looking into different types of water system e.g. replacing a wet cooling tower with a dry air-cooled system. However, this will not always be possible, in which case you will need to design, maintain and operate your water services under conditions that prevent or adequately control legionella growth.

This may include:

- avoiding ideal water temperatures and conditions for legionella growth

- keeping pipe lengths short to ensure water cannot stagnate

- ensuring that the proper control of water spray release

- avoiding materials that encourage legionella growth

- keeping the system and the water in it clean

- treating the water to prevent or control legionella growth

- monitoring control measures

- keeping records

7. Keep records

If you have five or more employees you must record any significant findings, including those who have been identified as particularly at risk, and the control measures put in place. These records should be retained throughout the period of time in which they are current, and for at least two years after this. They should include the following details:

- responsible person for conducting the risk assessment, and managing and implementing the scheme

- any significant findings from the risk assessment

- a written control scheme and details of implementing this

- details of the system’s state of operation

- results and dates of any monitoring inspection, test or check carried out

8. Test and monitor water for legionella bacteria

How frequently you test your water will depend on the system that you have and what your risk assessment has identified. For systems that are open, such as cooling towers, evaporative condensers and spa pools, testing should be carried out at least quarterly. This will likely be less for enclosed systems, as they are not open to the elements and significant contamination.

Testing can be carried out either by the operator, as long as they are trained to do so and are properly supervised, or a service provider.

9. Review your processes

It is important to regularly review your risk assessment to check your performance and ensure it is still appropriate. As yourself the following questions to help you decide if your process needs updating:

It is important to regularly review your risk assessment to check your performance and ensure it is still appropriate. As yourself the following questions to help you decide if your process needs updating:

- Do you have a risk assessment in place for the system?

- Does the risk assessment contain a description of your system?

- Does the risk assessment conclude there is no significant risk?

- If the risk assessment identifies a significant risk then:

- Is there a written control scheme in place addressing the risks?

- Have you identified at least one responsible person in writing?

- Are the roles and responsibilities of all staff involved clearly defined in writing, and are they appropriately trained?

- If external contractors are used, are their roles and responsibilities clearly defined, in writing, and has their competence been checked?

- Have you considered all other health and safety issues?

10. Check if you have any other duties

Depending on what systems you have, you may have additional responsibilities.

Notification of Cooling Towers and Evaporative Condensers Regulations 1992

Under this act, you must notify your local authority in writing, if you have a cooling tower or evaporative condenser on site, and include details about where it is located, and also update them when they are no longer in use.

Reporting of Injuries, Diseases and Dangerous Occurrences Regulations (RIDDOR)

You must report any legionellosis cases in employees who have worked on cooling towers or hot and cold water systems that are likely to be contaminated with legionella.

Alcohol and Drug Awareness & Legionella training courses are essential tools in reducing the risk of these health and safety hazards. Make sure you don’t miss out on our 10% off deal on these courses, available until the end of July. Simply enter the code ‘summer10’ at checkout to save!

Read more Top 10 Tips blogs here.

To keep up to date with the latest health & safety news and advice, follow us on social media: