❤ Valentine’s Day Course Offer! ❤

To celebrate Valentine’s Day on Friday 14th February, we are offering 50% off our Communications online training course with the code ‘Love20’ – valid for this weekend only! This course will help you to improve your personal and business communication skills on both a verbal and non-verbal level, so that your everyday interactions are more productive and meaningful. This will be especially useful if you feel like you need to overcome barriers to effective communication in your personal relationships, such as when talking to your partner feels like talking to a brick wall sometimes!

To celebrate Valentine’s Day on Friday 14th February, we are offering 50% off our Communications online training course with the code ‘Love20’ – valid for this weekend only! This course will help you to improve your personal and business communication skills on both a verbal and non-verbal level, so that your everyday interactions are more productive and meaningful. This will be especially useful if you feel like you need to overcome barriers to effective communication in your personal relationships, such as when talking to your partner feels like talking to a brick wall sometimes!

To learn more about the course, take a look on our website.

Flybe Fined £100K After Worker Fell Into Lift Shaft

Flybe Ltd was fined after a HSE investigation of a worker falling into a lift shaft at Exeter Airport uncovered health and safety failings. On 15 May 2016, a 34-year-old employee was moving a loaded lift trolley in the tool department of Hanger 2 when he fell into the lift shaft to the bottom floor and suffered injuries. Although the exact cause of the incident could not be established, the HSE investigation found that the lift doors had a fault which meant that they defaulted to locked. As a result, the emergency door release key was being used by employees while the lift doors remained locked. Flybe Ltd pleaded guilty to breaching Section 2(1) of the Health and Safety at Work Act 1974 and has been fined £100,000 and ordered to pay costs of £9,963.16.

Flybe Ltd was fined after a HSE investigation of a worker falling into a lift shaft at Exeter Airport uncovered health and safety failings. On 15 May 2016, a 34-year-old employee was moving a loaded lift trolley in the tool department of Hanger 2 when he fell into the lift shaft to the bottom floor and suffered injuries. Although the exact cause of the incident could not be established, the HSE investigation found that the lift doors had a fault which meant that they defaulted to locked. As a result, the emergency door release key was being used by employees while the lift doors remained locked. Flybe Ltd pleaded guilty to breaching Section 2(1) of the Health and Safety at Work Act 1974 and has been fined £100,000 and ordered to pay costs of £9,963.16.

Read more on the case from the HSE.

Three Firms Fined For Student Block Fire Safety Failings

The main contractor was among three firms ordered to pay fines totalling £670,000 after admitting fire safety failings at a building used for student accommodation in Leeds. Trinity Halls on Woodhouse Street had only one available fire escape which was compromised due to combustible materials, putting at serious risk the 27 students who had moved in, in September 2016. The court heard the students had moved into the building on the upper ground floor while other floors were still under construction. There were a string of other failures which contributed to the significant risk including lack of appropriate fire alarms and detection, exposed timber framing, the storage of flammable items on stairwells and no markings indicating fire escape routes. The failings came to light in September 2016 after a concerned father called West Yorkshire Fire and Rescue Service (WYFRS) to report the building. He had been dropping his daughter off to live there but became concerned by the state of the premises and would not let his daughter stay.

The main contractor was among three firms ordered to pay fines totalling £670,000 after admitting fire safety failings at a building used for student accommodation in Leeds. Trinity Halls on Woodhouse Street had only one available fire escape which was compromised due to combustible materials, putting at serious risk the 27 students who had moved in, in September 2016. The court heard the students had moved into the building on the upper ground floor while other floors were still under construction. There were a string of other failures which contributed to the significant risk including lack of appropriate fire alarms and detection, exposed timber framing, the storage of flammable items on stairwells and no markings indicating fire escape routes. The failings came to light in September 2016 after a concerned father called West Yorkshire Fire and Rescue Service (WYFRS) to report the building. He had been dropping his daughter off to live there but became concerned by the state of the premises and would not let his daughter stay.

Read more on the case from SHPOnline.

Companies Fined After Worker Dies In Explosion

Materials Movement Ltd and P J Labour Services Ltd have been fined after a worker was killed in an explosion at a demolition site. On 16 March 2017, 54-year-old Stephen Hampton, working at a site on Swains Lane in Camden, London, was killed when an old fuel storage tank he was cutting up exploded and the end of the vessel struck him causing fatal injuries. A HSE investigation found both contractors failed in their duties to effectively plan, manage and monitor control measures to address the risks associated with the demolition of a site that contained fuel tanks. The standards for this type of work are well known, established and clear. Materials Movement Ltd pleaded guilty to breaching Regulation 15(2) of Construction (Design and Management) Regulations 2015 and has been fined £33,000 and ordered to pay costs of £7,675.38. P J Labour Services Ltd pleaded guilty to the same charge, resulting in a fine of £33,000 and costs of £7,648.18. Speaking after the case, HSE inspector Ian Shearring said: “Mr Hampton had recently adopted two young boys and this incident leaves them, along with his wife, alone and struggling financially all for the sake of a bit more effort on both defendant’s parts. Both Materials Movement Ltd and P J Labour Services Ltd have today been held to account for killing Mr Hampton after failing to take adequate action to protect the health and safety of persons working on their site”.

Materials Movement Ltd and P J Labour Services Ltd have been fined after a worker was killed in an explosion at a demolition site. On 16 March 2017, 54-year-old Stephen Hampton, working at a site on Swains Lane in Camden, London, was killed when an old fuel storage tank he was cutting up exploded and the end of the vessel struck him causing fatal injuries. A HSE investigation found both contractors failed in their duties to effectively plan, manage and monitor control measures to address the risks associated with the demolition of a site that contained fuel tanks. The standards for this type of work are well known, established and clear. Materials Movement Ltd pleaded guilty to breaching Regulation 15(2) of Construction (Design and Management) Regulations 2015 and has been fined £33,000 and ordered to pay costs of £7,675.38. P J Labour Services Ltd pleaded guilty to the same charge, resulting in a fine of £33,000 and costs of £7,648.18. Speaking after the case, HSE inspector Ian Shearring said: “Mr Hampton had recently adopted two young boys and this incident leaves them, along with his wife, alone and struggling financially all for the sake of a bit more effort on both defendant’s parts. Both Materials Movement Ltd and P J Labour Services Ltd have today been held to account for killing Mr Hampton after failing to take adequate action to protect the health and safety of persons working on their site”.

Read more on the case from the HSE.

HSE Report Reveals Just 1 in 5 Monitors Asthma Risk

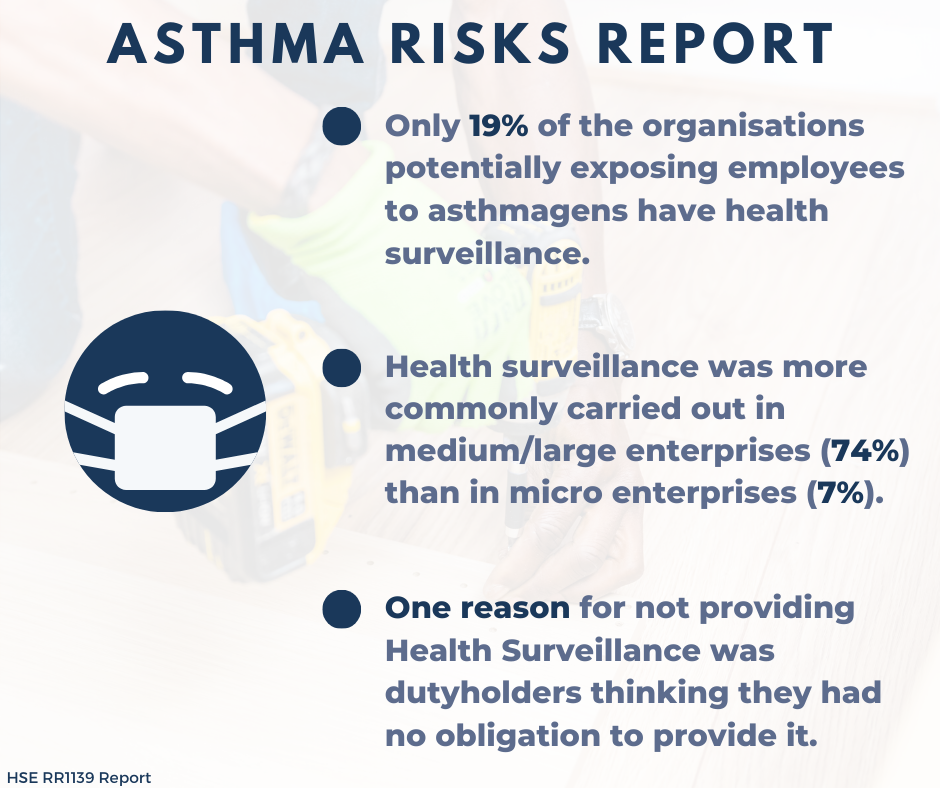

RR1139: Uptake and quality of health surveillance for occupational asthma in the woodworking, baking and motor vehicle repair sectors presents research into the levels of uptake and quality of health surveillance for occupational asthma in three industry sectors at increased risk of occupational asthma: woodworking; baking; and motor vehicle repair. It reported that only 1 in 5 (19%) of the organisations potentially exposing employees to asthmagens have health surveillance. Telephone interviews were held with employers from 457 organisations, of which 67% reported carrying out risk assessments. Risk of exposures that might cause occupational asthma (in the view of the dutyholder) was reported in 42 (27%) motor vehicle repair enterprises, in 78 (52%) woodworking workplaces and in 95 (62%) bakeries. Equivalent statistics for the specific industry sectors under consideration were 14% for the woodworking sector, 17% for motor vehicle repair sector and 24% for the bakery sector. Reporting by the organisations surveyed showed that health surveillance was more commonly carried out in medium/large enterprises (74%) than in micro-enterprises (7%). About a third delivered health surveillance in-house and two-thirds used an external provider. The research revealed that some dutyholders who were not providing health surveillance thought that they had no obligation to provide health surveillance, did not need to provide it because they were very small organisations or regarded the cost as a burden.

RR1139: Uptake and quality of health surveillance for occupational asthma in the woodworking, baking and motor vehicle repair sectors presents research into the levels of uptake and quality of health surveillance for occupational asthma in three industry sectors at increased risk of occupational asthma: woodworking; baking; and motor vehicle repair. It reported that only 1 in 5 (19%) of the organisations potentially exposing employees to asthmagens have health surveillance. Telephone interviews were held with employers from 457 organisations, of which 67% reported carrying out risk assessments. Risk of exposures that might cause occupational asthma (in the view of the dutyholder) was reported in 42 (27%) motor vehicle repair enterprises, in 78 (52%) woodworking workplaces and in 95 (62%) bakeries. Equivalent statistics for the specific industry sectors under consideration were 14% for the woodworking sector, 17% for motor vehicle repair sector and 24% for the bakery sector. Reporting by the organisations surveyed showed that health surveillance was more commonly carried out in medium/large enterprises (74%) than in micro-enterprises (7%). About a third delivered health surveillance in-house and two-thirds used an external provider. The research revealed that some dutyholders who were not providing health surveillance thought that they had no obligation to provide health surveillance, did not need to provide it because they were very small organisations or regarded the cost as a burden.

Read more on the report from IOSH.