Safety Net Rigging TechniquesSafety Net Riggers are often required to work at height which puts them, and others around them, at significant risk of hazards related to working at height. Regulation 6 of The Work at Height Regulations 2005 (WAHR) details a simple hierarchy for managing work at height: Avoid work at height where ever reasonably practicable, Prevent a fall if it is not reasonably practicable to avoid working at height, then adopt the most suitable method or working and select the most suitable equipment for work at height which prevents falls occurring; and finally, if it is not reasonably practicable to prevent the risk of a fall, measures should be taken to mitigate the distance and consequences of the fall. With assistance from the HSE, FASET (the trade association and training body for the safety net rigging and temporary safety systems industry) suggest a recommended hierarchy of controls when rigging safety netting which considers the WAHR:

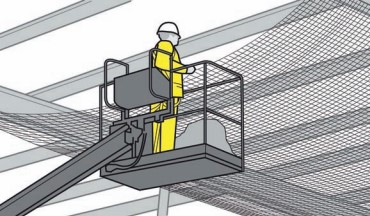

1. Rig /De rig remotely using remote attachment devices  Remote attachment device. Remove attachment devices eliminate the need to work at height allowing the installer to attach the netting from the platform below. However, there are several limitations with remote attachment devices; firstly, they are limited in the height that they can attach the net at, the higher the reach required the more difficult it can be to attach the netting, additionally using this type of equipment can increase the risk of musculoskeletal injuries. These devices are often dependant on the framework arrangement, weather conditions and net size. Fixings such as rope ties may still need an operative to work at height to attach by hand. Remote attachment devices can only be attached to I and C section beams. 2. Rig / De rig using powered access MEWPs  Rigging using MEWPs When remote attachment devices are not suitable MEWPs are generally considered to be the best method of access for rigging safety nets. As is the case for whenever MEWPs are being used, this matters entirely on the site conditions and if suitable ground exists. A safe system of work should be developed between rigging contractors and clients as early as possible as early planning can, for example, allow floors on multi-storey builds to be concreted in time to allow access for small MEWPs to access higher levels.

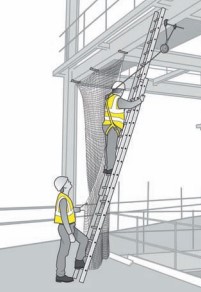

3. Rig / De rig using ladders – recommended maximum height of 4.5meters  Use of ladders. Ladders are limited to instances where a risk assessment can demonstrate that they are the overall least risk option available by WAHR. Detailed information on safe use of ladders can be found in the HSE document INDG455 “safe use of ladders and stepladders. A brief guide”. Important points to highlight regarding safety net rigging include duration of use. Ladders should only be used for short duration tasks and, although safety net rigging may require the use of ladders throughout the day, it may only take 2 minutes to attach a net at its desired location and therefore this is seen as a short duration activity at each location. FASET guidance says riggers using ladders MUST be wearing a fall arrest system attached to a suitable anchor point. FASET recommends that ladders are only used up to a height of 4.5meters (measured from the floor to the underside of the steel). Finally, although ladders are usually required to be tied off this is not reasonably practicable in most rigging circumstances as they can be required to be moved several hundred times per day. Due to this, ladders must always be footed during use when they are not tied off.

4. FASET specialist rigger: Industrial Climbing Techniques  Specialist rigger using rope access techniques. In some situations, it may not be practicable to use remote attachments, MEWPs or ladders; this may often be the case when access is limited, and the working height exceeds 4.5meters. To avoid this, attention must be paid to the access and egress during planning to ensure that all risks are reduced as far as reasonably practicable. However, if this is not the case, specialist riggers employing industrial climbing techniques can be called upon for the installation of safety nets. Riggers undertaking this work must hold a blue skilled CSCS safety net rigger card and completed the FASET specialist rigger qualification. Specialist riggers are only trained to work in areas where a rescue can be affected quickly and efficiently in a vertical direction only to the preceding level or to the ground using standardised rescue procedures and equipment. Some industrial climbing access may require riggers to work at height for the full duration using roped access techniques; in this situation the rigger should be trained by the Industrial Roped Access Trade Associated (IRATA) and hold a valid IRATA card. Roped access technicians can be verified online at https://irata.org/verify .

5. Mobile access towers Generally, mobile access towers are not recommended for rigging and de-rigging safety netting; this is due to three main reasons including the increased possibility of overturning caused by imposed side loadings where nets are being positioned for rigging/derigging and where border ropes are pulled taught. Snagging of nets on components such as brace hooks and outrigger couplers. The tendency for operatives to omit or remove stabilisers or outriggers. Towers may be used only in situations where the following criteria are met: 1) Floor surface is flat, level and solid. (corrugated floor surfaces are not suitable) 2) There is sufficient floor space to deploy stabilisers/outriggers 3) Towers are always located below each net attachment point to ensure operatives do not reach over guardrails. 4) Provision of adequate training and supervision to ensure bad practices are not permitted. 5) additional measures are taken to prevent overturning, such as use of ballast weights or tying in, which should be under the direction of the manufacturer.

(All information correct as of 1st February 2019) |