Proper asbestos protection is essential – conditions caused by asbestos exposure is responsible for approximately 5,000 deaths in the UK every year.

While personal protective equipment (PPE) for asbestos includes a number of necessary components, this blog will focus on RPE.

What does RPE stand for in PPE?

Respiratory Protective Equipment (RPE) is a specific type of PPE designed to protect the individual against the inhalation of airborne hazardous substances. RPE should only be used as a last resort when adequate exposure control cannot be achieved by any other means.

Respiratory Protective Equipment (RPE) is a specific type of PPE designed to protect the individual against the inhalation of airborne hazardous substances. RPE should only be used as a last resort when adequate exposure control cannot be achieved by any other means.

What respiratory protective equipment is needed for asbestos?

Ordinary dust masks are not effective in preventing the inhalation of asbestos fibres and dust.

Ordinary dust masks are not effective in preventing the inhalation of asbestos fibres and dust.

Cheap masks may save a few quid, but they do not provide adequate protection against airborne asbestos fibres.

You will need to use a specific respirator designed to be used with asbestos. With this in mind, suitable RPE should have a UK-assigned protection factor (APF) of at least 20 or more.

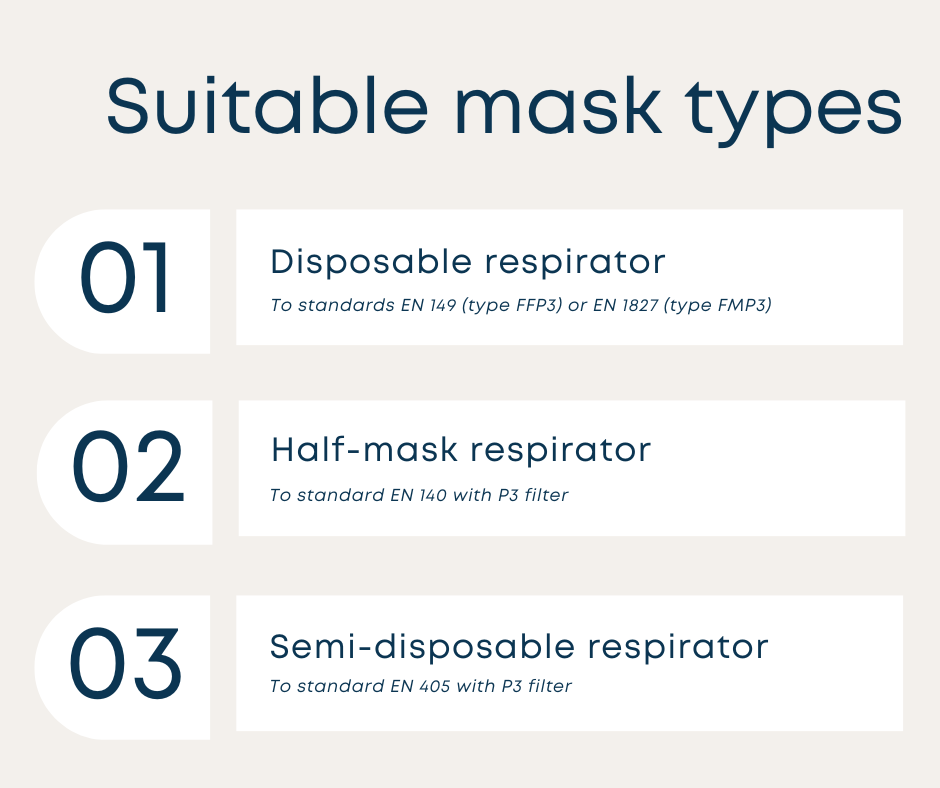

This is the level of protection the mask offers. Suitable types of masks that offer this required level of protection include:

- Disposable respirator to standards EN 149 (type FFP3) or EN 1827 (type FMP3).

- Half-mask respirator (to standard EN 140) with P3 filter.

- Semi-disposable respirator (to EN 405) with P3 filter

Please take into account that this type of equipment isn’t suitable for people with beards or stubble. In these instances, hooded respirators are required.

The equipment isn’t suitable for long periods of continuous use in this situation cannot be avoided then power assisted equipment will be needed in this situation.

With half-mask respirators please ensure you change the filters regularly – your supplier should be able to advise you how often.

Make sure you dispose of used disposable masks or any used filters as asbestos waste.

What should RPE training include?

Respiratory Protective Equipment (RPE) is unlikely to provide the best level of protection possible if the wearer does not know how to store, maintain and use the equipment in the correct way.

Respiratory Protective Equipment (RPE) is unlikely to provide the best level of protection possible if the wearer does not know how to store, maintain and use the equipment in the correct way.

As set out in The Control of Asbestos Regulations 2012, employers must ensure that there has been suitable and adequate training provided to all operatives, supervisors or anyone else who has responsibility for RPE in the workplace before its used.

This training should include:

- How to select the most suitable RPE for the job.

- How to check the equipment is working properly

- What to do if the equipment isn’t working properly

- How to securely put it on.

- How to ensure it fits properly

- How to identify worn or defective parts and how to replace them

- How to properly store RPE

- How to safely dispose of single-use RPE

- How to clean non-disposable RPE

- The importance of record keeping and why regular inspection is required

This training should also be supplemented with regular refresher training provided at a suitable period. Refresher training is especially important for those who wear or maintain RPE on an infrequent basis.

How can WA Management help?

WA Management offer bespoke risk assessments for any activities that may expose your workers to dust asbestos, complete with recommended controls to mitigate any negative effects. We also provide both in-person and online asbestos awareness training options, and have a range of RPE available in our PPE catalogue. Get in touch to learn more!

Asbestos Awareness and Control of Hazardous Substances training courses are essential tools in protecting the health of your workers. Make sure you don’t miss out on our 10% off deal on these courses, available until the end of February. Simply enter the code ‘OccHealth10’ at checkout to save!

Read more Consultant’s blogs here.

To keep up to date with the latest health & safety news and advice, follow us on social media: