In this blog, WA Management continues its mission to shed a light on the risks and hazards present throughout the workplace. With Dust as our feature Hazard of the Month, we bring you our key opinions on the dangers of these flying particulates and the methods in which they can be safely managed. For our fact file on Dust, see our previous blog HERE.

Is Dust As Dangerous As Other Hazards?

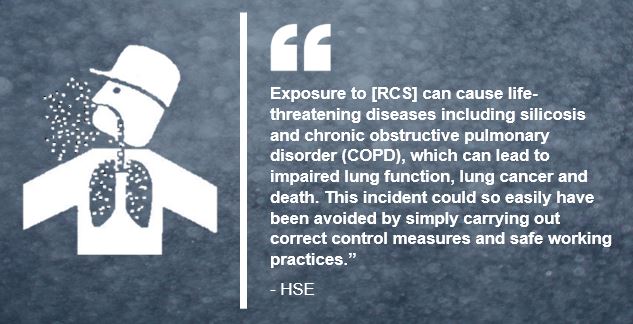

True, compared to other hazards, Dust is not as capable of causing serious illnesses through one-off cases of exposure. However, for those consistently working in close proximity to Dust, a lack of proper protection can gradually lead to life-threatening illnesses and fatalities. Take Silica for example; research conducted by the HSE estimates that exposure to Silica may be responsible for 500 fatalities a year for those who have worked in construction. With the Workplace Exposure Limit (WEL) for Silica being smaller than a 1 pence coin, it therefore comes as no surprise to hear that a playground and landscaping contractor was fined by the HSE this week for continually failing to protect its employees from Respirable Crystalline Silica (RCS).

Thus, with Dust posing such important health and safety risks, the question to be asked is…

What Can I Do To Manage The Risks?

When it comes to mitigation, our fact file HERE covers a number of available options which help to combat the dangers that Dust can pose for employees. However, in addition to these options, we at WA Management are also here to help employers assess different work processes that can reduce and prevent the formation of Dust. Here are some of the options also recommended by the HSE:

When it comes to mitigation, our fact file HERE covers a number of available options which help to combat the dangers that Dust can pose for employees. However, in addition to these options, we at WA Management are also here to help employers assess different work processes that can reduce and prevent the formation of Dust. Here are some of the options also recommended by the HSE:

- Materials – A great quantity of Dust is formed by cutting materials down to the correct size and shape.By acquiring the correct dimensions of a needed material beforehand, Dust-producing processes such as cutting can be avoided.

- Tools – In cases where reshaping materials is unavoidable, the use of the right tools can still reduce the formation of Dust. As an example, the HSE recommends using a Block Splitter instead of a Cut-Off Saw for pavement blocks.

- Method – Changing the work to use Dust-free methods can also prevent Dust from becoming present. One such method can include using Liquid Adhesives as a substitute for drilling holes for Nails.

Will These Processes Make My Work Dust-Free?

In industries such as construction, the formation of some Dust will be almost inevitable. Therefore, to minimise the dangers of Dust as much as possible, a holistic approach will be needed. Preferably, an approach that considers different processes to reduce Dust, in conjunction with options that protect workers from harmful Dusts when they become airborne, will be the most beneficial. As can be seen, there are a number of considerations that need to be taken into account before commencing on any work. This can cause the issue of Dust to come across as a difficult hazard to control given its airborne nature. Yet, the variety of different processes and options available for the industry can allow for safe and efficient mitigation, provided that good knowledge and awareness is present.

In industries such as construction, the formation of some Dust will be almost inevitable. Therefore, to minimise the dangers of Dust as much as possible, a holistic approach will be needed. Preferably, an approach that considers different processes to reduce Dust, in conjunction with options that protect workers from harmful Dusts when they become airborne, will be the most beneficial. As can be seen, there are a number of considerations that need to be taken into account before commencing on any work. This can cause the issue of Dust to come across as a difficult hazard to control given its airborne nature. Yet, the variety of different processes and options available for the industry can allow for safe and efficient mitigation, provided that good knowledge and awareness is present.

Knowing whether you’ve taken full account of Dust can seem daunting, especially if the project to be undertaken is a large one. However, at WA Management, our expert consultants are here to provide the right guidance at the right time for when such projects can seem increasingly confusing. If you’re about to plan a new project, get in touch with us HERE for a free consultation!

Conclusions

To summarise, try first by looking at what ways you can conduct your work differently to avoid Dust as much as possible. Once this has been accomplished, look into the protective options available for you and your employees so that any airborne Dust can be kept away from the body.