Hot works refer to processes that produce heat, sparks, or flames – such as welding, cutting, grinding, and sawing.

There are a number of personal safety risks associated with hot works such as burns to skin or eyes. Furthermore, without proper precautions, hot works potentially post a significant risk of catastrophic harm due to fire or explosions. As a result, controlling these hazards require specific measures to minimize the risk.

What are the hazards of hot works?

Other than the risk of physical harm from the equipment you are using, such as coming into contact with a grinding disc, the immediate risks of hot works come from contact with the hot elements. Most commonly this would be sparks flying into operators’ eyes or molten metal contact with skin.

Other than the risk of physical harm from the equipment you are using, such as coming into contact with a grinding disc, the immediate risks of hot works come from contact with the hot elements. Most commonly this would be sparks flying into operators’ eyes or molten metal contact with skin.

Conversely there are significant risks from hot elements coming into contact with combustible and flammable materials starting fires or potentially explosions. This puts those completing the work and others at significant risk.

How do you risk assess hot works?

As normal practice in health and safety management to determine the levels of risk from planned hot works a suitable and sufficient thorough risk assessment should be undertaken. Particular focus should be given to the task that is being undertaken, substances present and the environment in which the hot works are being undertaken.

There are a number of high-risk situations that would require careful consideration if hot works were to be undertaken. Any work within proximity to flammable or explosive substances presents a heightened risk. Furthermore, any work in confined spaces or areas which have restricted access/egress may also limit emergency procedures.

How do you control hot works risks?

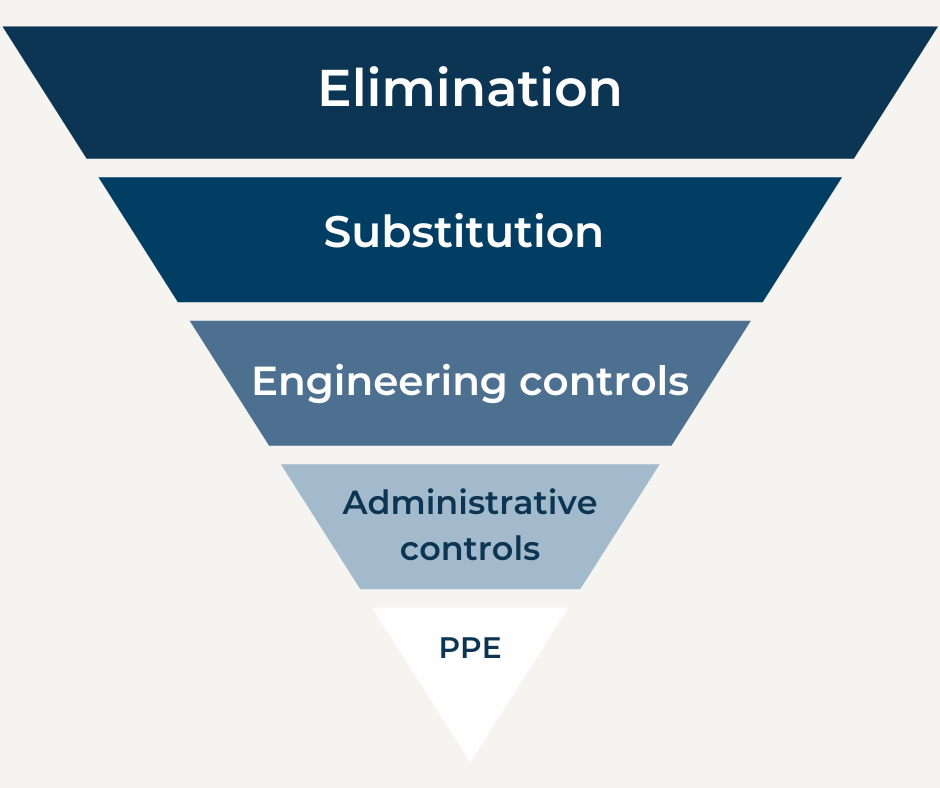

As indicated in the hierarchy of controls the primary method of controlling hot works is to avoid hot works if necessary. This is particularly important in areas where there is heightened risk such as with flammable substances present or in confined spaces. Common methods of eliminating the risk is to have hot works undertaken off site, such as using prefabricated parts, or by using new methods such as cold cutting and joining.

As indicated in the hierarchy of controls the primary method of controlling hot works is to avoid hot works if necessary. This is particularly important in areas where there is heightened risk such as with flammable substances present or in confined spaces. Common methods of eliminating the risk is to have hot works undertaken off site, such as using prefabricated parts, or by using new methods such as cold cutting and joining.

There are situations, however, where hot works is not always avoidable. In which case generally the works are managed through a permit to work system. This is an administrative control that presents as a document of authority passing specific responsibilities to those undertaking the works to ensure specific conditions are met. Examples of controls on a hot works permit include requirements to Isolate services, remove all flammable/combustible materials from the area, requirement to wear non-static clothing or use non-sparking tools and conduct a 60 minute fire watch post works.

How can WA Management help?

WA Management offer a Risk Assessment online training course suitable or all workers involved in developing a risk assessment and/or enforcing procedures in the workplace.

Risk Assessment and Prevent Duty courses are essential tools in protecting the welfare of your workers. Make sure you don’t miss out on our 10% off deal on these courses, available until the end of July. Simply enter the code ‘welfare10’ at checkout to save!

Read more Consultant’s blogs here.

To keep up to date with the latest health & safety news and advice, follow us on social media: