Regular maintenance in industrial facilities is essential but can pose serious risks if not managed properly. Lockout/Tagout (LOTO) procedures protect workers during these tasks by controlling hazardous energy.

LOTO stations support this safety process by centralising all necessary tools, ensuring quicker, more consistent, and compliant lockouts—reducing accidents, downtime, and confusion.

What is a Lockout Tagout station?

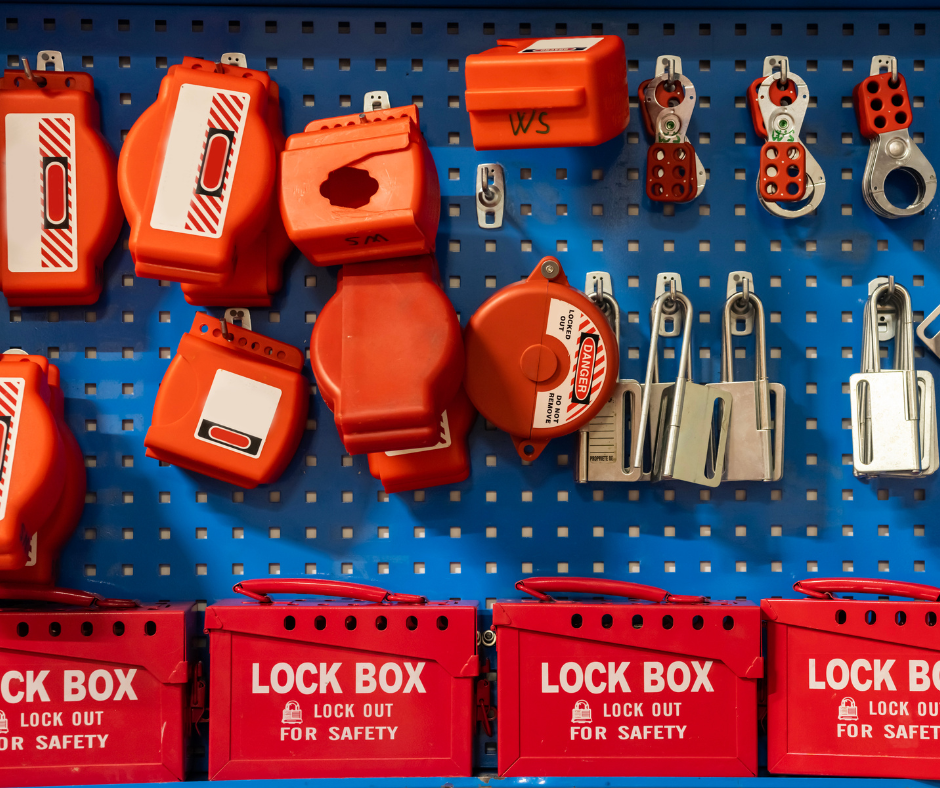

A LOTO (lock-out tag-out) or lockout station, is a designated storage area for devices used to physically isolate and disable equipment where there are no local means of isolation.

A LOTO (lock-out tag-out) or lockout station, is a designated storage area for devices used to physically isolate and disable equipment where there are no local means of isolation.

Preventing the hazardous release of energy during maintenance, repairs or electrical infrastructure alterations.

Lockout stations offer a visual sign of ongoing maintenance by enforcing a standardised system across departments, teams or contractors through devices such as colour-coded locks and tags.

These devices can sometimes include the name of the person responsible for isolation of the equipment, enabling cross-team coordination by communicating the equipment’s status and avoiding conflicting work and unintentional re-energising.

Creating a centralised location in a high visibility area for your organisation’s lockout station ensures all devices are easily accessible and encourages consistent use, reinforcing a unified safety culture.

Whilst there is no specified legal requirement to use a lockout station, it enables employers to comply with The Health and Safety at Work etc. Act 1974 and The Electricity at Work Regulations 1989 by taking reasonable precautions against the risk of death or injury from electricity in work activities, ensuring that conductors and equipment cannot be energised whilst work is taking place.

What are the different types of Lockout Tagout stations?

There are several types of lockout station, each are designed to suit different work environments, hazards and level of use. Whilst the most common are wall mounted stations, portable stations and lockout cabinets:

Wall Mounted

Wall Mounted stations are typically found near work areas or in control rooms where there is a requirement for real time supervision of lockout procedures.

These units can be open for unrestricted easy access or enclosed to support cleanliness and extend the lifespan of the devices.

They may also incorporate shadow boards, which provide accountability by allowing teams to quickly identify missing items and encourage good housekeeping and compliance with other procedures such as Lean manufacturing 5S principle.

Portable

Portable stations provide compact mobile kits that can be carried to different work areas and are best for the construction environment where the environment rapidly evolves or in remote, off-site locations.

Cabinets

Cabinets provide closed storage, allowing organisations to protect LOTO devices from dust, moisture and other contaminants within the environment.

They can also enhance security by restricting access to LOTO devices to authorised users only.

- Padlock cabinets include storage hooks that compartmentalise and keep padlocks in an organised manner that allows prompt retrieval and management

- Key cabinets focus on the associated keys for LOTO devices not just padlocks. Providing visual real time tracking and key management procedure for key holders by providing a unique ID for each key corresponding to an associated slot.

How to organise Lockout Tagout stations

Lockout stations provide the foundation for safe maintenance practice in any environment where release of hazardous energy poses a risk to workers.

Lockout stations provide the foundation for safe maintenance practice in any environment where release of hazardous energy poses a risk to workers.

Whilst implementation of a LOTO procedure can be considered best practice, without effective organisation and control of the stations physical assets the procedure can easily fail to meet compliance.

When implementing a lockout station, you should consider:

- The location by placing your station strategically in a central, high-traffic area close to the equipment or areas often serviced. You should also consider the frequency of the stations use and whether multiple stations are needed, such as high-use machines having their own dedicated station.

- Provide clear and concise labelling that can be easily communicated and reduce confusion. This may also incorporate a colour coded system where each team our lockout purpose such as electrical isolation or mechanical isolation has their own colour-coded system. You may also wish to incorporate images/names of the isolation personnel or guides next to each station to reinforce any training provided to aid new or temporary workers.

- Consider methods of traceability that provide accountability to track operations. These can include logbooks to automated digital asset management devices.

- Regularly check and review the effectiveness by incorporating lockout stations into inspections and audits to ensure equipment is functional, fully stocked and nothing is damaged or missing.

- Provide clear and comprehensive training to ensure all employees can execute the process of retrieval, application and return of the devices linked to the lockout station. Ensuring effective leadership of the process through reinforcement and positive acknowledgement of positive contributions.

- Consider customisable stations where needed for multilingual and task specific purposes. Whilst research suggests that by providing a customised solution a positive psychological impact can be created, enhancing engagement and increasing compliance rates through perception of personal tailoring.

How can WA Management help?

WA Management offer a Lock Out Tag Out online training course suitable as part of an induction process or as refresher training.

Electrical Safety and Lock Out Tag Out training courses are essential tools in staying safe when working near or with electricity. Make sure you don’t miss out on our 10% off deal on these courses, available until the end of May. Simply enter the code ‘elec10’ at checkout to save!

Read more Consultant’s blogs here.

To keep up to date with the latest health & safety news and advice, follow us on social media: