Respiratory Protective Equipment (RPE) is a type of PPE designed to protect the wearer from inhaling hazardous substances in the form of dust, mist, gas or fumes. It is vital that RPE to be effective it is suitable for the wearer, task and environment, while also adequately addressing and reducing exposure to the hazard – enough so that the wearer is protected.

To help you gain a better understanding of respiratory protective equipment and how it can be used, we have answered some frequently asked questions. Read on to learn more!

When should you use respiratory protective equipment?

You should wear respiratory protection equipment (RPE) whenever you are conducting works that, despite controls in place, there is still a likelihood contaminated air is present.

You should wear respiratory protection equipment (RPE) whenever you are conducting works that, despite controls in place, there is still a likelihood contaminated air is present.

Your employer could have identified be the presence of a respiratory sensitiser through the completion of a COSHH Assessment, respirator sensitisers are such things as:

- Isocyanates (vehicle spray paint, foam manufacture)

- Flour, Grain, and Hay

- Electric Soldering Flux

- Wood Dusts

- Laboratory Animals

Respiratory sensitisers are dusts, vapours, mists, or substances that, when inhaled, cause an irreversible reaction. It is not always an immediate reaction, over long or frequent exposure durations your body will begin to react. After this initial reaction, it may only take a minute amount of the sensitiser to cause a reaction.

Wearing RPE as stated in your company’s risk assessment or COSHH assessment will protect you from these respiratory sensitisers along with many other chemicals i.e., asbestos, that are hazardous to health.

How do you select appropriate respiratory protective equipment?

Selection should be made with input from the wearer(s); individual differences in face shape, facial hair and scars can all impact the effectiveness of RPE, for example the effectiveness of full-face masks can be impacted by glasses with side arms.

Selection should be made with input from the wearer(s); individual differences in face shape, facial hair and scars can all impact the effectiveness of RPE, for example the effectiveness of full-face masks can be impacted by glasses with side arms.

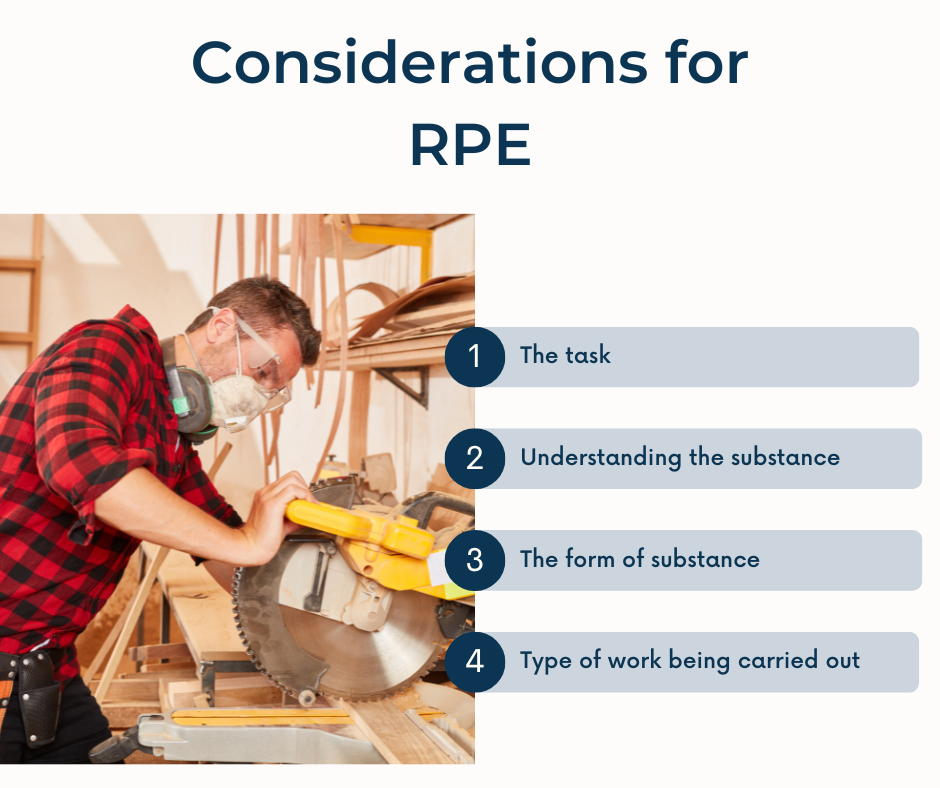

Other considerations need to be made, such as:

- The task. This is the work-rate and wear-time of the RPE. For short duration work it is recommended that for tight—fitting (unpowered) RPE should only be worn for an hour as it can become uncomfortable.

- An understanding of the substance and the amount of it, certain substances have a set workplace exposure limit, exceeding this limit could require the wearer to equip different RPE to prevent the risk.

- What form it is in, is it a vapour, gas, solid or liquid. Not all variations of RPE can be used with all forms, for example a disposable half mask respirator is only effective against solid or liquid particles.

- The type of work being carried out, those conducting work with lead are required under the Control of Lead at Work Regulations 2002 to wear suitable respiratory equipment, defined as having an assigned protection factor of 20 (e.g. FFP3 half mask with P3 filter).

It is common for people to forget that the chosen RPE needs to be compatible with other required PPE or essential wear. If you are required to wear a full-face mask and a safety helmet, the full-face mask could loosen the fit of the helmet, in the event of a falling object the helmet may dislodge and prove ineffective.

To ensure effectiveness against the hazardous substance and compatibility with required PPE a face fit test should be conducted. As with clothing, there is no universal size of RPE, there is no one size fits all. Conducting a face fit test ensures the selected RPE is also an appropriate fit for the wearer.

What are the types of respiratory protective equipment?

There are two different types of respiratory equipment:

There are two different types of respiratory equipment:

- Respirators (Non-powered) – relies on the wearer to bring in air through a filter to be purified.

Respirators can be disposable or non-disposable. An example of a disposable respirator is one we commonly used or saw used during the COVID-19 pandemic, they come in three classifications which determine their protection factor. FFP1 (Factor 4), FFP2 (Factor 10) and FFP3 (Factor 20)

- Breathing apparatus (Powered) – where a supply of purified air is sent through a breathing hose for the wearer from an independent source.

There is a variety of types of breathing apparatus – one we may have seen is standard duration breathing apparatus (SDBA) which the London Fire Brigade has reported to use. This is due to the fact it only has one cylinder which is stored on the firefighters’ back to provide adequate mobility.

Both are available with a tight-fitting facepiece which is dependent on having a secure seal around the wearers face to be effective.

Whereas loose-fitting facepieces are only available as breathing apparatus as they are dependent on the sufficient supply of air from the cylinder to be effective against the hazardous substance, e.g., hoods, helmets or visors.

How can WA Management help?

WA Management offer qualitative face fit testing, carried out by our qualified face fit testers, available either on-site as a half or full day of testing, or at our offices for individual testing.

We also sell a wide range of PPE at competitive prices, including many RPE options – get in touch to learn more!

PPE and Lock Out Tag Out training courses are essential tools in protecting your workers from hazards in the work place. Make sure you don’t miss out on our 10% off deal on these courses, available until the end of March. Simply enter the code ‘ppe10’ at checkout to save!

Read more Consultant’s blogs here.

To keep up to date with the latest health & safety news and advice, follow us on social media: