Manual handling in the workplace is the second largest cause of non-fatal workplace injures making up 17% in 22/23 (1). Manual handling can lead to a number of injuries, most notably musculoskeletal injuries– injuries and conditions that can cause pain to the back, joints and limbs.

The Manual Handlings Regulations 1992 set out a clear hierarchy of measures that should be followed to prevent associated risks, this follows that you should avoid hazardous manual handling operations so far as reasonably practicable, assess the risk where this cannot be avoided and reduce the risk to as low as reasonably practicable.

How do you choose the right manual handling equipment?

To choose the correct manual handling equipment we must first conduct a manual handling risk assessment.

To choose the correct manual handling equipment we must first conduct a manual handling risk assessment.

This is a requirement of The Management of Health and Safety at Work Regulations 1999 but also has specific elements stated by the manual handling regs.

We must consider:

- Task: Consider what is being done, is it repetitive, involve twisting/holding loads away from the body, a work rate, vertical movement or carrying long distance etc?

- Individual: Does the task involve unusual capability, pose a risk to health or require special information and training etc?

- Load: Are they heavy, bulky, difficult to grasp or large etc?

- Environment: are there restrictions on posture, variations in level, poor lighting conditions etc?

- Other: are there any other factors that have not been considered.

Follow the completion of this risk assessment it may be established that an adequate control would be to use manual handling equipment so we can reduce the risk so far as reasonably practicable.

What equipment is needed for manual handling?

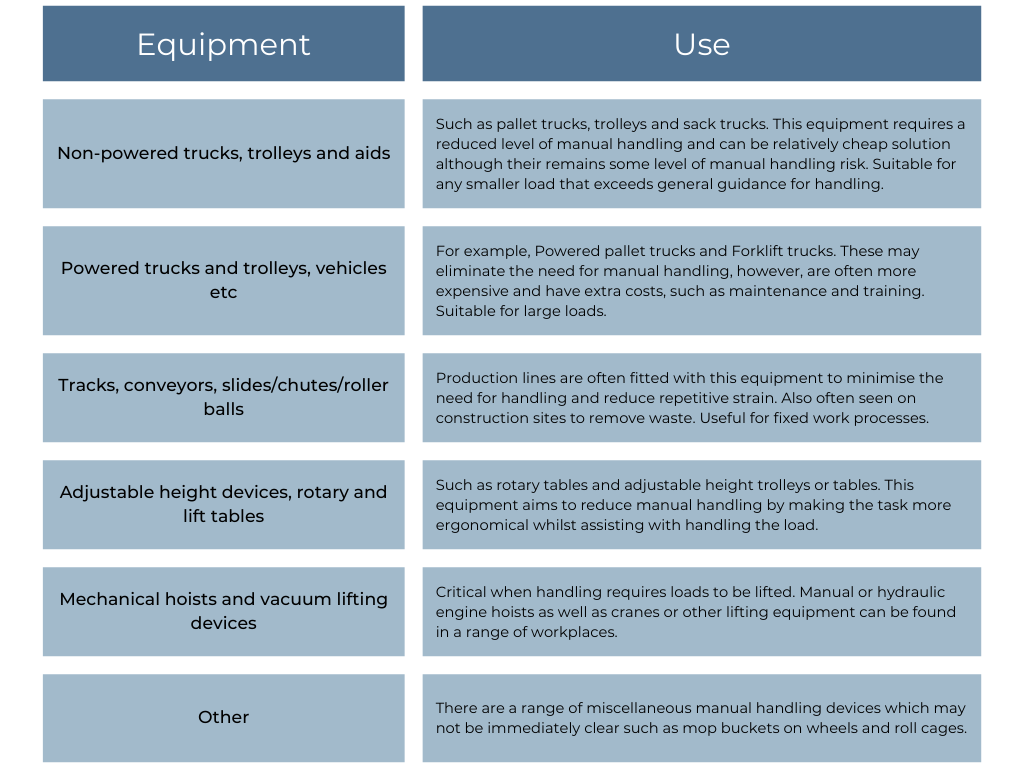

Given he wide range of manual handling tasks that may be undertaken there is inevitably a range of solutions that may or may not be useful in any given scenario. Below is outlined some of the main types of manual handling equipment.

How often should manual handling equipment be inspected?

The frequency and content of an inspection is entirely dependent on the equipment you choose to use.

The frequency and content of an inspection is entirely dependent on the equipment you choose to use.

We are guided primarily by The Provision and Use of Work Equipment Regulations and The Lifting Operations and Lifting Equipment Regulations.

In general, all equipment should have a pre use check, for sack and pallet trucks this can be a short visual inspection, however, for more complex equipment such as a forklift truck a predetermined checklist may be required to be completed.

Work equipment should also get recorded periodic inspections. For simple lower risk equipment an annual 12 month recorded inspections may suffice; however, some hoists may require 7 day recorded inspections, 6-month thorough examination of attachments and 12 month through examination of the hoist itself.

In essence we should manage work equipment through a maintenance schedule, which dictates what inspections equipment requires based on legislation, manufacture recommendations and our own risk assessment process.

How can WA Management help?

WA Management offer an online manual handling training course which provides awareness education for anyone in the workplace, but especially those who lift, lower, push, pull, carry, move, hold, restrain or set down a load during their daily tasks.

We also offer bespoke risk assessments for any activities that may involve manual handling.

Manual Handling and Slips, Trips & Falls training courses are essential tools in preventing accidents and injuries in the workplace.. Make sure you don’t miss out on our 10% off deal on these courses, available until the end of August. Simply enter the code ‘mh10’ at checkout to save!

Read more Consultant’s blogs here.

To keep up to date with the latest health & safety news and advice, follow us on social media: